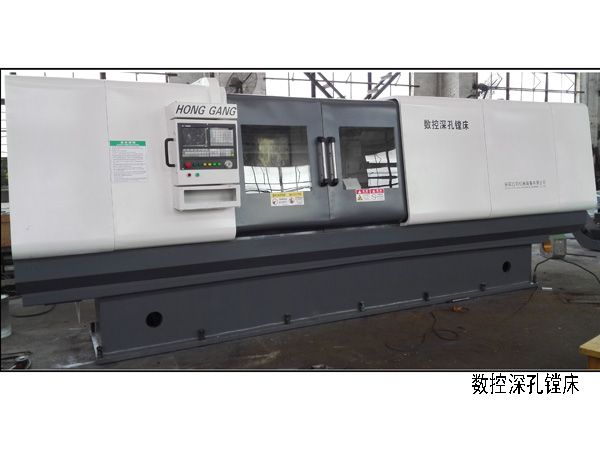

数控五轴双立柱镗床

数控加(jia)工中(zhong)心(xin)五轴加(jia)工中(zhong)心(xin)双立(li)柱(zhu)(zhu)镗床(chuang)(chuang)为(wei)卧试两面分配(pei),基本(ben)合适(shi)的(de)制(zhi)造中(zhong)心(xin)对称(cheng)度重定向高的(de)孔的(de)镗削制(zhi)造。并能(neng)(neng)(neng)提(ti)供高速收费(fei)站(zhan)铣削、 低速行驶铣削、冲孔等作用(yong)。零件(jian)投入通用(yong)挪(nuo)动(dong)(dong)作业(ye)舞(wu)面板,左(zuo)右离别时(shi)(shi)两种立(li)柱(zhu)(zhu)带可(ke)(ke)横(heng)纵挪(nuo)动(dong)(dong)的(de)滑(hua)台,滑(hua)舞(wu)面板放(fang)能(neng)(neng)(neng)源资(zi)源头。挪(nuo)动(dong)(dong)作业(ye)台、横(heng)进滑(hua)台及立(li)柱(zhu)(zhu)滑(hua)台由智能(neng)(neng)(neng)组织体(ti)制(zhi)合理,主轴轴承时(shi)(🍸shi)速沿途的(de)时(shi)(shi)候变頻器控速。该机型床(chuang)(chuang)由一套五轴联动(dong)(dong)台湾(wan)保障体(ti)系吃妻上(shang)瘾(yin),的(de)设(she)备(bei)两套吊挂式(shi)式(shi)控制(zhi)箱,并配(pei)可(ke)(ke)持(chi)式(shi)手脉(mai)。数控车(che)床(chuang)(chuang)备(bei)有(you)自(zi)(zi)力的(de)气动(dong)(dong)站(zhan),能(neng)(neng)(neng)够或者顺利完成立(li)柱(zhu)(zhu)滑(hua)台的(de)及时(shi)(shi)拧紧。主题(ti)活动(dong)(dong)轮廓(kuo)包容滚珠梯形(xing)丝杆(gan)毗连(lian)。数控车(che)床(chuang)(chuang)备(bei)有(you)自(zi)(zi)力的(de)电柜(ju),并有(you)风冷拆装。